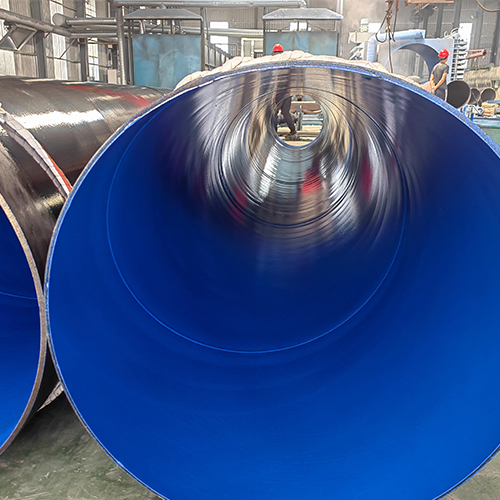

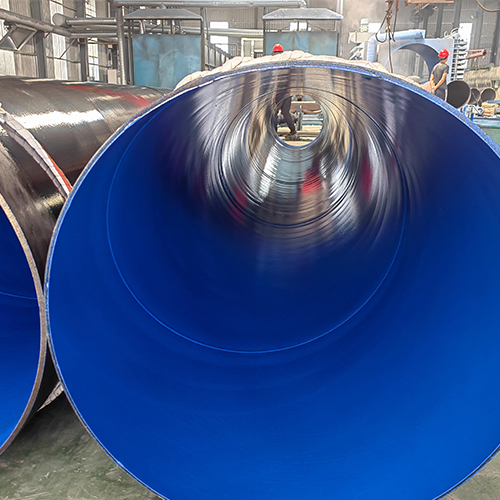

Double-sided submerged arc welded 3PE anti-corrosion steel pipe is a type of steel pipe welded using a straight seam double-sided submerged arc welding process. It features a three-layer anti-corrosion structure: the outermost layer is high-density polyethylene (PE), the middle layer is an adhesive layer, and the inner layer is epoxy powder (EP). These three layers combine to form a complete anti-corrosion system that effectively isolates the pipe from moisture and oxygen in the soil, resists microbial erosion, and significantly extends its lifespan.

What are its advantages?

Compared to ordinary steel pipes, its advantages are significant:

- Strong corrosion resistance: The three-layer structure works synergistically, providing a corrosion protection life of over 50 years, far exceeding that of ordinary pipes;

- High welding quality: Double-sided submerged arc welding technology ensures uniform weld strength, eliminating defects such as porosity and slag inclusions, resulting in excellent overall pipeline sealing;

- Wide applicability: The steel pipe base can be made of different materials such as Q235B and X60, adapting to complex working conditions such as high pressure and low temperature.

Applications:

Applications:

- Long-distance oil and gas pipelines: When transporting natural gas and crude oil, 3PE anti-corrosion can resist soil corrosion and reduce the risk of leakage;

- Municipal water supply/drainage: In urban underground pipe network renovation, it replaces galvanized pipes, avoiding water pollution;

- Chemical industry: When transporting corrosive media such as acids, alkalis, and sewage, the inner epoxy powder layer can directly isolate corrosion;

- Marine engineering: Cross-sea pipelines and oil pipelines at ports in coastal areas, resisting seawater salt corrosion.